Technical areaTechnologies

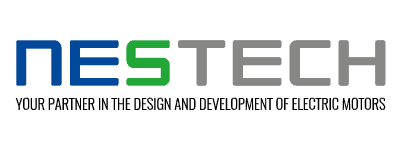

Laser cutting

Latest generation fiber laser cutting system, 2 KW power, accuracy +/- 0.025 mm, 3000×1500 mm working table.

Laser beam extremely thin and concentrated, in order to produce precision and accurate laminations.

Ideal for prototyping, small series, special applications and service.

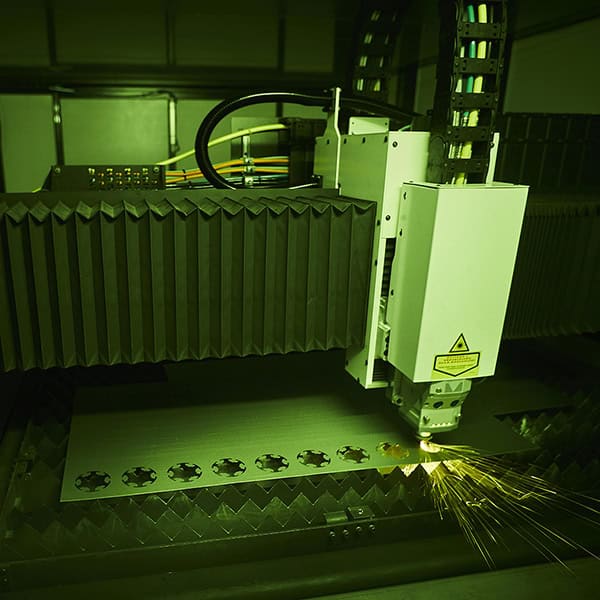

Stacking

Single laminations are stacked with special tooling, which is designed by our Technical Office with 3D software and manufactured specifically for each project, in order to guarantee the highest quality.

Pressing is done by means of tie rods and springs or hydraulic presses, depending on the size and quantity.

Bonding

We use BACKLACK technology for stacks assembly. Each lamination is cut from a pre insulated sheet of electrical steel with a thermosetting polymer; when subjected to a temperature of about 200°C, the polymer reacts and allows their bonding.

Welding

We are equipped with TIG and MIG welding for stator or rotor stacks. We can perform soldering or brazing of aluminum or copper bars with end plates for rotor stacks.

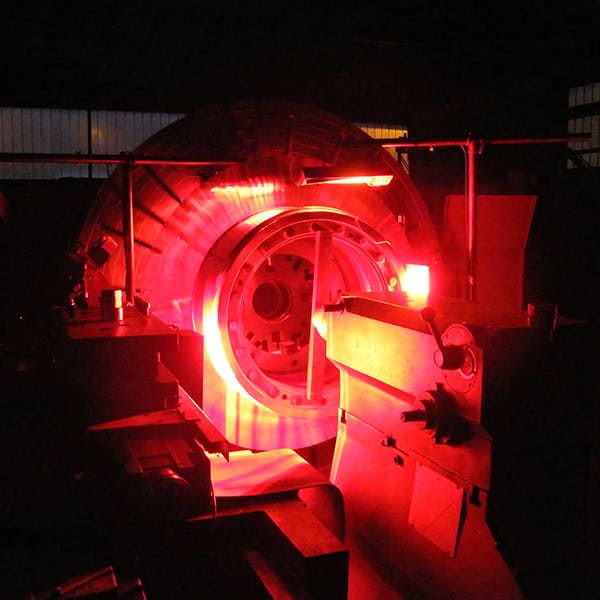

CNC Turning

Turning is performed on request on the assembled stator and rotor stacks, in order to guarantee tight tolerances.

Maximum diameter up to 2000 mm.

Machining

Mechanical machining is carried out on the assembled stacks. The products that are usually machined are the following:

- Stator stacks;

- Stacks for linear motors;

- Poles for AC and DC machines.

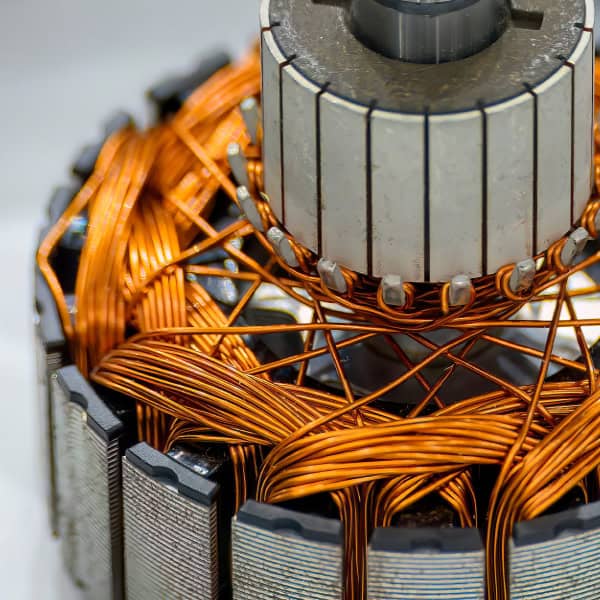

Windings

We offer a wide range of windings for stator stacks mainly made by hand, especially for prototypes and non-standard motors.

Engineering

We have a Technical Office with highly specialized staff and 3D software (Solid Edge) to design the stacking equipment and all the components that are made internally or in subcontracting.

We are able to carry out REVERSE ENGINEERING, issuing a technical drawing starting from a sample supplied by the customer.